|

RC Systems Application Note |

| November 2018, MARIETTA, GA ~ |

| Gas Detection of Tank Farms and Liquified Gases |

|

|

|

Chemical plants depend upon a continuous mass flow of their raw materials and final products from input

storage to output storage. When the materials are gases or liquids, the storage areas are known as a

“Tank Farms”. Efficient storage requires increasing the mass of gases through compression and

liquefaction. Tank Farms are usually made up from three different types of storage tanks which are

Pressure Tanks, Cryogenic Tanks and Atmospheric Tanks.

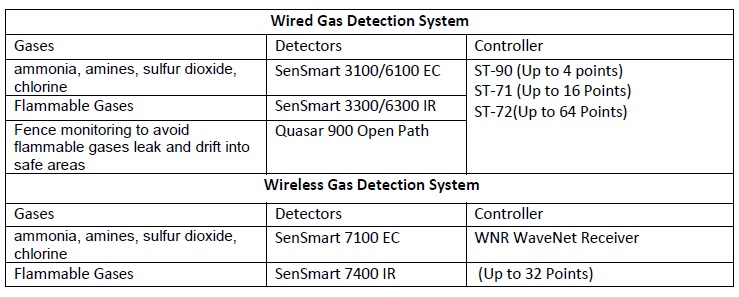

Typical gases stored in pressure tanks are ammonia, amines such as methyl amine, dimethyl amine, ethyl amine, and trimethyl amine, C3/C4-hydrocarbons such as propane, cyclopropane, propylene, butanes, butylenes, and butadiene, mixtures of propane and butanes called LPG (liquid petrol gas), ethyl chloride, ethylene oxide, chlorine, dimethyl ether, methyl chloride, phosgene, sulfur dioxide, nitrogen dioxide, and vinyl chloride. Pressure tanks are equipped with level indicators with alarm trips along with temperature sensors to continuously measure the interior temperature and activate a cooling sprinkler system in case of a temperature alarm. |

|

Safety relief valves control the internal pressure; releasing the gas into atmosphere or a flare system to be burnt. Either of these processes mean costly loss of product along with leading to potentially explosive of toxic atmospheres and the need for toxic and combustible gas detection.

Cryogenic Tanks

Cryogenic tanks require a complex cooling system and are therefore more expensive than pressurized storage tanks. However, cryogenic tanks are also safer since liquefaction occurs at atmospheric pressure. The combination of pressurized and cryogenic containment techniques are quite common. More and more gas stations and truck stops now have cryogenic LNG storage tanks to support LNG powered vehicles. Gas detection is very important for this application since LNG is odorless and invisible. Odorants the utility providers commonly add to natural gas cannot be added to liquefied methane. Low temperature cryogenic tanks are heavily insulated and a much of their volume is insulation only. These tanks contain liquefied gases such as argon (- 186 °C), ethane (- 88 °C), ethylene (- 104 °C), helium (- 268 °C), methane (-161 °C), oxygen (- 183 °C), and nitrogen (- 196°C) at temperatures near their boiling point and atmospheric pressure. Besides oxygen and nitrogen, ethylene is one of the most commonly used products world-wide and many tank farms store ethylene which should be monitored with gas detection.

Atmospheric Tanks

Is the gas detection system needed for bulk storage of toxic and/or flammable substances, liquefied or pressurized? National laws and regulations require high safety standards when the amounts of dangerous goods exceed a given limit. NFPA says: Continuously monitored low temperature sensors or flammable gas detection systems shall sound an alarm at the plant site and at a constantly attended location if the plant site is not attended continuously. Flammable gas detection systems shall activate an audible and a visual alarm at not more than 25 percent of the lower flammable limit of the gas or vapor being monitored. (NFPA 59A, Standard for the Production, Storage, and handling of liquefied Natural Gas(LNG), Chapter 12.4.2 Gas Detection) Tank farms require gas detection primarily for explosion protection and early leak detection. Explosion protection means tripping alarms at concentrations of 20% to 40% LEL and promptly activating countermeasures at the site (informing operators, technicians and fire brigade) and/or switching countermeasures (closing solenoid valves, activating cooling showers, water sprayers). Tank loading and unloading might be accompanied by large leaks when connecting the appropriate pipes to tank trucks. Early leak detection is accomplished by detecting and alarming at lower concentrations (e.g. 10 % LEL). Even with temperature and pressure gauge sensors, small leaks (hairline cracks) are difficult to detect without gas detection. However, over long periods these small leaks mean costly loss of product and may even become a large leak with hazardous consequences. Tank farms must have a safety distance between the tanks so in case of a fire, the probability of affecting adjacent tanks is minimized. Some applications even strip out the cooling water to monitor for dissolved flammable, e.g. ethylene. RC Systems’ Recommendation:

|

Pressure Tanks

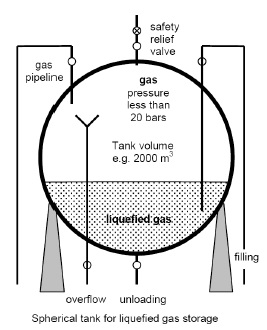

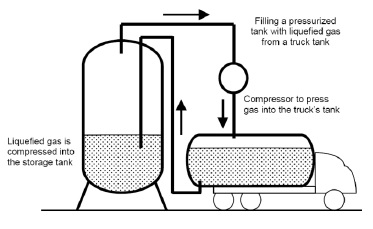

Pressure Tanks Tank filling is by two connecting tubes; one for the

gas and one for the liquid. The gas is drawn out

from the storage tank a compressor pressurizes it

into a tank truck. This pressurization then forces the

liquefied gas back into the storage tank. This is

potentially dangerous process especially while

making the necessary tube connections. Gas leaks

can occur and gas detection is highly

recommended. The most common gases stored

pressurized tanks are ammonia, chlorine and LPG.

Tank filling is by two connecting tubes; one for the

gas and one for the liquid. The gas is drawn out

from the storage tank a compressor pressurizes it

into a tank truck. This pressurization then forces the

liquefied gas back into the storage tank. This is

potentially dangerous process especially while

making the necessary tube connections. Gas leaks

can occur and gas detection is highly

recommended. The most common gases stored

pressurized tanks are ammonia, chlorine and LPG.