Laser line scanners used to profile billets

with repeatability and speed before scalping

Laser line scanners used to profile billets

with repeatability and speed before scalping

No reliance on manually measuring the deepest point of the billet before the scalping process

No reliance on manually measuring the deepest point of the billet before the scalping process

Develop shorter cycle times and avoid excessive material scrap

Develop shorter cycle times and avoid excessive material scrap

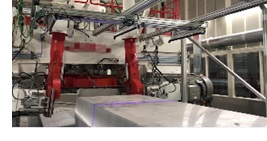

Inline Laser Measurement Before Scalping

Inline Laser Measurement Before Scalping

-

Measuring range: 5 mm – 1000 mm

-

Resolution: down to 0.8 microns

-

Large selection of cases and measuring ranges

-

Real-time 3D profiling can be created

The AccuProfile 820 Laser Scanner creates 2D profiles and 3D point cloud data using laser triangulation measurement principles. The AP820 is compact and performs very well on shiny or jagged targets. Edge scanning pose little problem due to the units auto gain and high dynamic range.

The AccuProfile 820 Laser Scanner creates 2D profiles and 3D point cloud data using laser triangulation measurement principles. The AP820 is compact and performs very well on shiny or jagged targets. Edge scanning pose little problem due to the units auto gain and high dynamic range.

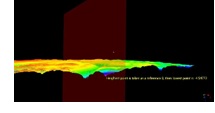

Laser Measurement To Avoid Excessive Material Scrap

Laser Measurement To Avoid Excessive Material Scrap

Acuity lasers produce a 3D point cloud of the raw billet surface giving way for software to accurately calculate the coordinates of the highest and deepest levels of the surface. The laser measurements bring clients the advantage of shorter cycle times and avoid excessive material scrap.

Acuity lasers produce a 3D point cloud of the raw billet surface giving way for software to accurately calculate the coordinates of the highest and deepest levels of the surface. The laser measurements bring clients the advantage of shorter cycle times and avoid excessive material scrap.

For more information on Acuity’s measuring capabilities

click here

For more information on Acuity’s measuring capabilities

click here

To

discuss your application and receive a product recommendation, please e-mail

To

discuss your application and receive a product recommendation, please e-mail

sales@flwse.com

|

|