|

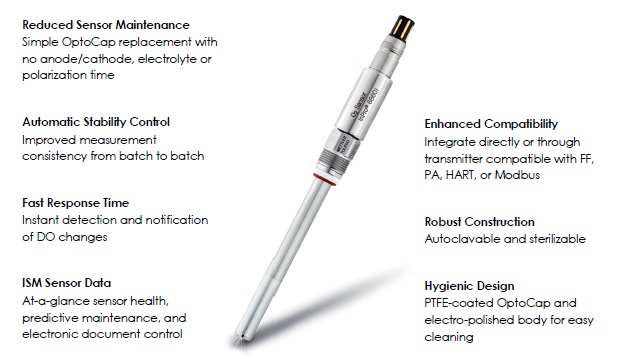

Mettler Toledo's InPro 6860i Dissolved Oxygen Sensor

Designed for Biopharmaceutical Applications

|

December 2019,

MARIETTA, GA ~

The METTLER TOLEDO InPro 6860i sensor incorporates the latest in optical oxygen technology to simplify

sensor maintenance and provide reliable measurement over extended periods. In cell culture and

fermentation, in-line control of dissolved oxygen (DO) ensures that the correct amount of oxygen for

proper cell metabolism and glycosylation is supplied at all times. Reliable measurement of dissolved

oxygen levels throughout the process is required for optimal yield and batch-to-batch consistency. Sensor

health and maintenance are critically important. With Intelligent Sensor Management (ISM), maintenance

becomes predictable, failure in the process is avoided, and traceability is simple. December 2019,

MARIETTA, GA ~

The METTLER TOLEDO InPro 6860i sensor incorporates the latest in optical oxygen technology to simplify

sensor maintenance and provide reliable measurement over extended periods. In cell culture and

fermentation, in-line control of dissolved oxygen (DO) ensures that the correct amount of oxygen for

proper cell metabolism and glycosylation is supplied at all times. Reliable measurement of dissolved

oxygen levels throughout the process is required for optimal yield and batch-to-batch consistency. Sensor

health and maintenance are critically important. With Intelligent Sensor Management (ISM), maintenance

becomes predictable, failure in the process is avoided, and traceability is simple.

Seamless Transition Through the Product Life Cycle

The InPro 6860i dissolved oxygen sensor was designed specifically for use in the

biopharmaceutical industry. The 6860i can easily transition from benchtop use

in research and development, through scale-up, and into the production

environment.

Wide range of communication options Wide range of communication options

120, 220, 320, 420 & 590mm sensor lengths 120, 220, 320, 420 & 590mm sensor lengths

Housings to accommodate a variety of vessels Housings to accommodate a variety of vessels

CIP, SIP & autoclave compatible CIP, SIP & autoclave compatible

User-friendly connections and power options for simple integration User-friendly connections and power options for simple integration

Plug-and-measure installation in under a minute Plug-and-measure installation in under a minute

|

Digital Installation

Digital signal are not affected by humidity, electrical

interference or long cable runs. It also enables reporting on a

large number of parameters. With digital communication and ISM,

critical sensor information is communicated to the controller. |

|

Analog Installation

Integrate cutting-edge optical technology into existing

installations. Communicate directly with a PLC or biocontroller.

Access critical sensor information through iSense. |

For more information:

www.mt.com/6860i For more information:

www.mt.com/6860i

To request additional information

please contact FLW Southeast

sales@flwse.com To request additional information

please contact FLW Southeast

sales@flwse.com

|

|

| |