|

Acuity’s AR200 Selected for Dimensioning Solution!

June 2019,

MARIETTA, GA ~

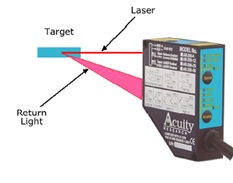

It is a complicated process to create vision-guided robotics, imaging systems, and dimensioning systems. A lot can go wrong. For a company like Artemis Vision, a machine-vision solution provider out of Denver, Colorado it is vital to make every design decision count. All the parts in their machine systems must work together to ensure stability and repeatability. When it came time to develop their latest dimensioning solution, they chose AR200 lasers from Acuity!

The Dimensioning System developed by Artemis Vision features a pair of two lasers that calculate thickness to high precision on foam boards used in the manufacturing of wind turbine blades. They chose AR200 lasers because they are compact, durable, and deliver reliable measurements between six and fifty millimeters. With this automated vision system, their customers are able to step away from manual measurement processes that are inconsistent, expensive, and time-consuming, and implement a solution that ensures that products always meet their designed specifications.

This Dimensioning System is reliable, repeatable and easily integrated into current operations. It can be scaled up or down depending on the needs of their customers. This translates to time and money saved, and products that are measured correctly every time. All this is made possible by a laser-based vision system that utilizes durable, dependable, and accurate AR200 lasers from Acuity.

|