|

November 2019,

MARIETTA, GA ~

Conductivity, sometimes expressed as ppm TDS (parts per million total

dissolved solids), is the method used to monitor mineral concentration. Many

industrial boilers use periodic grab sample conductivity measurements and

manual setting of the blowdown rate. This results in large swings in mineral

content between grab sample measurements caused by changes in boiler

load, make up water quality, etc. that can cause periods of scaling, corrosion

or excessive blowdown. November 2019,

MARIETTA, GA ~

Conductivity, sometimes expressed as ppm TDS (parts per million total

dissolved solids), is the method used to monitor mineral concentration. Many

industrial boilers use periodic grab sample conductivity measurements and

manual setting of the blowdown rate. This results in large swings in mineral

content between grab sample measurements caused by changes in boiler

load, make up water quality, etc. that can cause periods of scaling, corrosion

or excessive blowdown.

A much improved strategy uses a continuous on-line conductivity measurement and automatic blowdown

control to maintain consistent mineral concentration and minimize corrosion and scaling under all

conditions. The Mettler Toledo Boiler Conductivity Sensor with its high temperature/pressure rating allows

continuous measurement directly in the blowdown line without the expense of a sample cooler or cooling

water flow for samples up to 250 psig (17 bar) at 392 °F (200 °C).

The Mettler Toledo Boiler Sensor combined with a M300 transmitter, provides a

continuous, accurate conductivity measurement with readout in µS/cm, mS/cm or

ppm TDS. The transmitter can be located up to 200 ft (61 m) away from the sensor

and retransmit alarm, control and/or analog signals even further. Automatic

blowdown control allows close management of boiler water quality and usually

reduces the amount of blowdown, saving a significant amount of energy. The Mettler Toledo Boiler Sensor combined with a M300 transmitter, provides a

continuous, accurate conductivity measurement with readout in µS/cm, mS/cm or

ppm TDS. The transmitter can be located up to 200 ft (61 m) away from the sensor

and retransmit alarm, control and/or analog signals even further. Automatic

blowdown control allows close management of boiler water quality and usually

reduces the amount of blowdown, saving a significant amount of energy.

Features Overview Features Overview

-

Minimize

corrosion & scaling with highest accuracy measurement and

consistent blowdown control

-

Reduce

energy costs with continuous monitoring & automatic control

-

Save

operations costs by direct measurement without sample cooler & cooling

water

-

Install

with flexibility of in-line mounting or side-stream flow housing

-

Use with versatile Thornton analog transmitters with choice of built-in control options

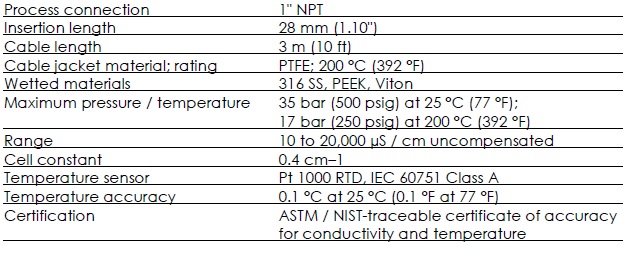

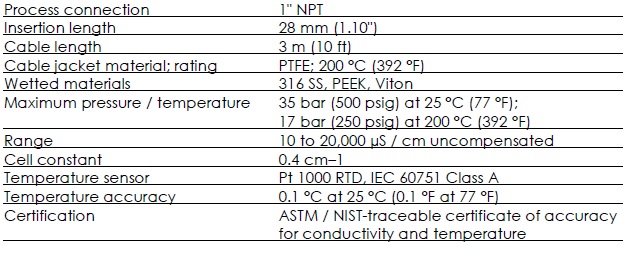

Boiler Water Conductivity Sensor

Specifications

To request additional information

please contact FLW Southeast

sales@flwse.com To request additional information

please contact FLW Southeast

sales@flwse.com

|

To request additional information

please contact FLW Southeast

To request additional information

please contact FLW Southeast